Automotive a-class surfacing?

What does it even mean?

Lets break it down one word at a time.

Automotive..

this basically just means the car industry

But it does have its implications. A car is typically among the most expensive things that a person buys in their lifetime. The industry was estimated to be worth roughly $3.8tr in 2022

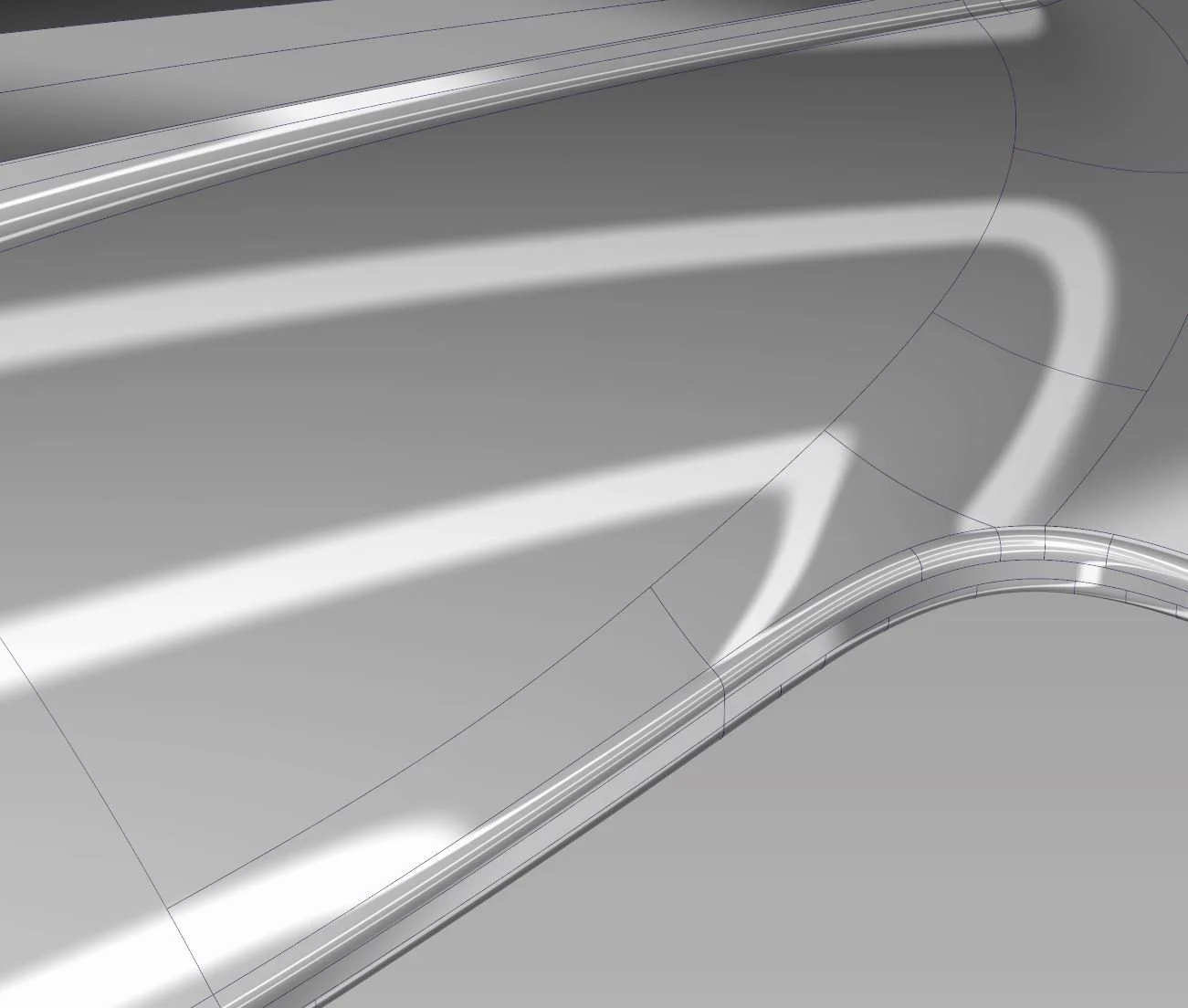

Cars are usually painted high gloss, so the shape of the car will affect how the paint reflects its surroundings. This is commonly called “highlights” and it plays a major roll in automotive design.

A-Class..

Probably the least known of these words

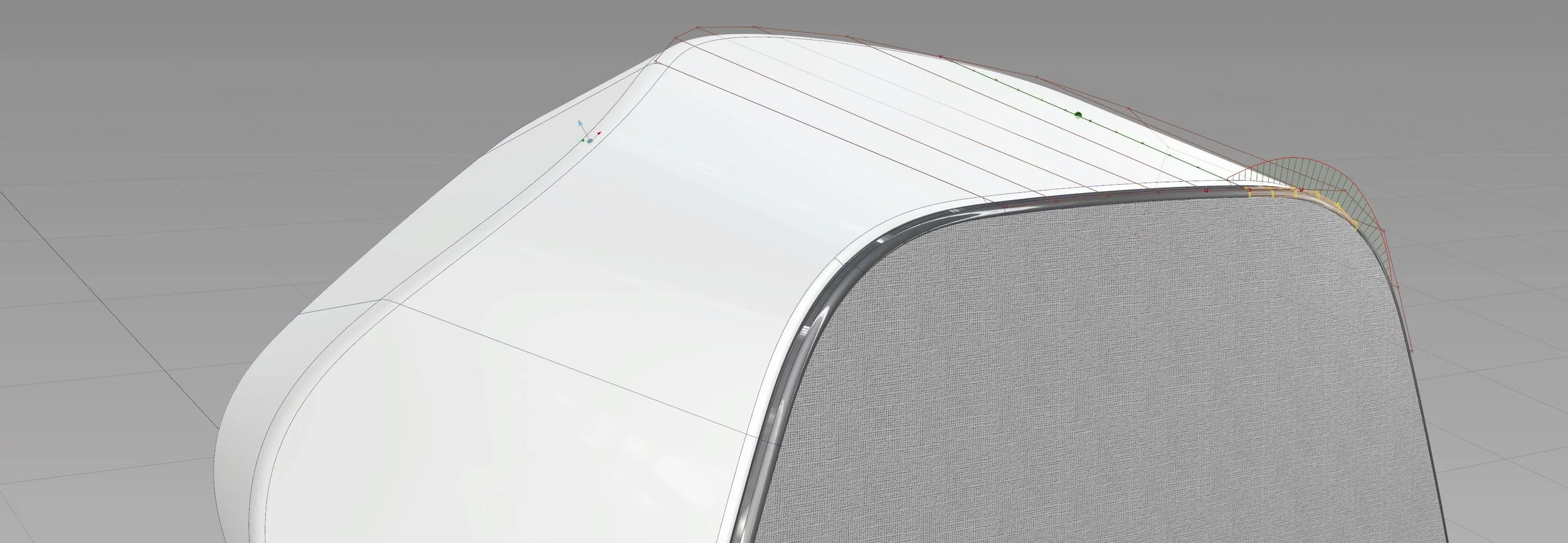

“A” is referring to A-surfaces. It is an industry way of saying that the surfaces are on the visible side of the finished product. As opposed to the B-surfaces that are on the inside of the finished product.

The “class” part is a way of saying; “these are standards and tolerances that apply”

So A-Class is saying “The surfaces will be the most visible so these are the standards and tolerances that apply to them.”

Surfacing..

this is just a form of modelling

A common form of cad style is called solid-modelling, this treats parts in a more lifelike way where they behave like solid objects.

But all CAD software renders only the surface of the parts. In a way of looking at it, all CAD models are hollow.

Surface modeling or “surfacing” is just an extrapolation of that concept. In my line of work we only build the a-surface since that is where our expertise lies. The b-surface usually has a different set of challenges that are better suited for the engineering team.

At the end of the project the A and B surfaces are joined together to make a solid part.

What it means

I don’t want to come off as elitist but the simple truth is. The only reason my job exists at all is because cars are in a league of their own.

These are probably the most scrutinized surfaces in any consumer product. They require both tools and skills not typical in product design. To add to that, more and more technology goes under the surface for every passing year.

A side mirror used to be a mirror in a frame on a swivel. Now it also includes, adjustment servos, several cameras, heating elements, turn signal, blind-spot detection, puddle light, power folding and circuits to control and monitor it all. This usually has to get crammed into a space as small as possible and still look good.

That is just the simple question of feasibility. Then we need to consider: production, assembly & service, legal demands for target regions, safety, ergonomics, aerodynamics and price.

Last point might seem a little strange since cars are so expensive but I have seen very heated debates over a $0.1 increase in a part cost. In all honesty, in most cases the margins are pretty slim. It is a far more vulnerable market than people might imagine. A new car is pretty much at the top on the list of the things people don’t buy when the economy takes a downward turn.